ATRP-E20: GTRI & ATRP at the 2025 International Production & Processing Expo

The latest Georgia Tech Research Podcast episode covers the 2025 International Production & Processing Expo (IPPE). Georgia Tech Research Institute's (GTRI) Agricultural Technology Research Program (ATRP) demonstrated two key projects: the poultry rehang shackle system by Dr. Konrad Ahlin and the autonomous chicken house monitoring robot, Go-Bot, led by Colin Usher.

At the 2025 International Production & Processing Expo (IPPE), Georgia Tech Research Institute's (GTRI) Agricultural Technology Research Program (ATRP) captured industry attention with two groundbreaking technology demonstrations. Highlighted in the latest Georgia Tech Research Podcast episode, hosted by Stephanie Richter, the expo showcased how ATRP continues to drive innovation in poultry production.

"IPPE is a fantastic event that allows us to showcase what our great folks do here at GTRI," said Doug Britton, ATRP program manager. "We get a chance to network, learn what's state-of-the-art, and build relationships crucial for driving our innovation forward."

The ATRP booth featured two key projects: the revolutionary poultry rehang shackle system by Dr. Konrad Ahlin and the autonomous chicken house monitoring robot, Go-Bot, led by Colin Usher.

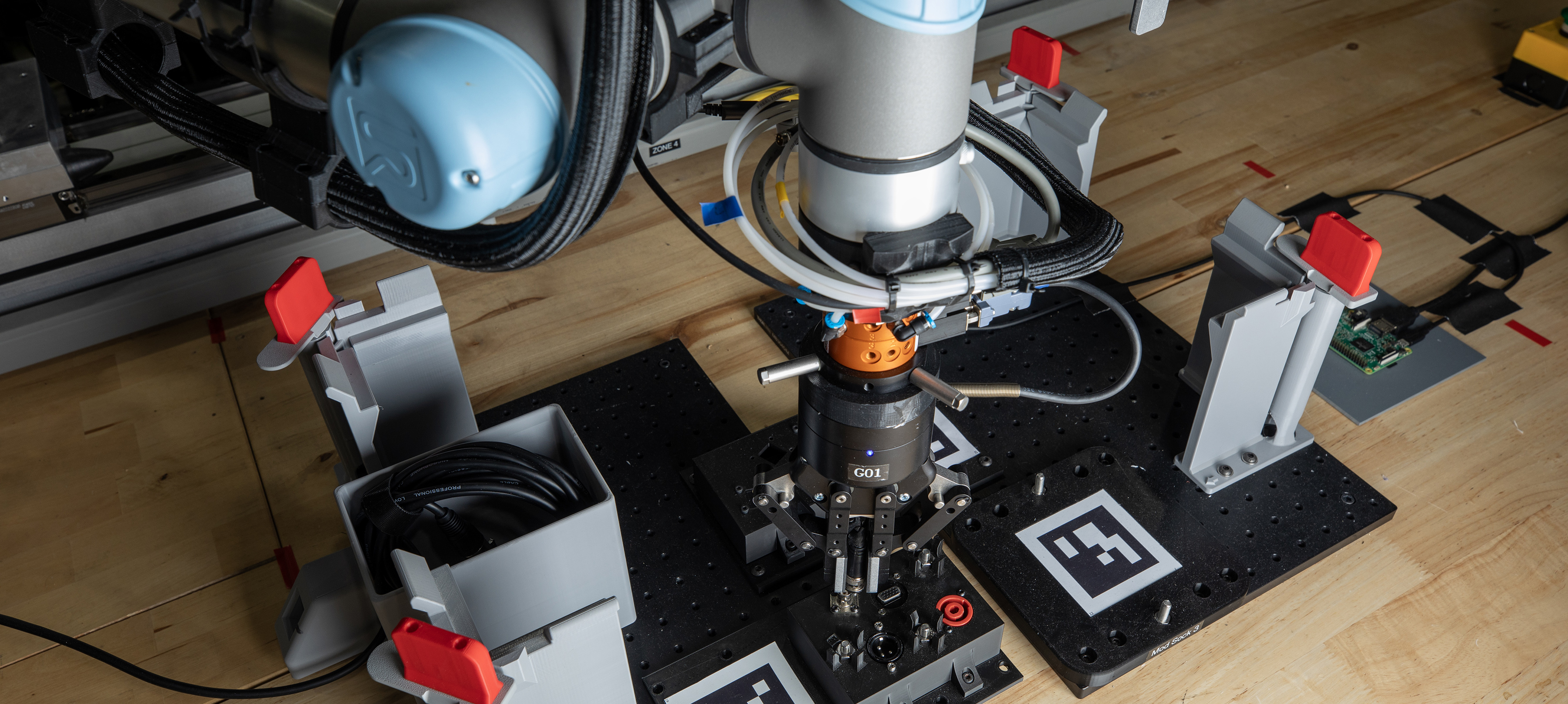

Konrad’s demonstration focused on improving safety and ergonomics in poultry processing. "We’re developing a system for performing the rehang action, simplifying a physically and mentally demanding job," explained Konrad. "Our device allows operators to push the birds onto a rehang mat, reducing the risks associated with manually hanging birds on fast-moving shackles."

Meanwhile, Colin Usher’s Go-Bot, a fully autonomous ground robot designed to monitor chicken houses and collect eggs, drew significant interest. "It started as a wild idea in 2014," Colin recalled. "The first time we showed it, farmers didn't ask about research—they just wanted to buy it. That blew our minds."

Alexis Noel on the GTRI SEEDlab

Alexis Noel, Ph.D., a senior research engineer at GTRI, manages the GTRI SEEDLab makerspace, which opened in September 2021. The SEEDLab, which includes 3D printers, laser cutters, and CNC machines, fosters creativity and collaboration among GTRI employees.

In the latest episode of the Georgia Tech Research Podcast, Alexis Noel, Ph.D., senior research engineer at the Georgia Tech Research Institute (GTRI), offers an inside look at the SEEDLab, GTRI’s first makerspace. This “small-but-mighty” facility has been a popular addition to GTRI, fostering creativity, collaboration, and hands-on engineering across disciplines.

Opened in September 2021, the SEEDLab (short for “Support for Early Engineering Design”)—is housed in the Baker Building and has quickly become a hub of activity for GTRI researchers, staff, and students. It provides access to cutting-edge tools, including multiple 3D printers, laser cutters, and CNC machines. Despite its compact 400-square-foot space, the lab serves a rapidly growing community. “There are over 300 GTRI employees who have room access to the SEEDLab,” says Alexis. “We have over 660 individuals who sign in during work hours every month.”

Alexis, who co-founded the SEEDLab with retired-but-working GTRI researcher Byron Coker, brings a decade-long passion for makerspaces to her role. She describes the lab as more than just a place to access tools—it’s a thriving learning community where GTRI personnel can develop new skills and bring ideas to life. “A makerspace is a collaborative community workspace where people can build and experiment while sharing tools, ideas, and expertise with other members,” she explains. “Unlike a machine shop, which requires significant training, a makerspace is designed to have a low barrier to entry, making it accessible to people with no prior experience.”

The SEEDLab supports a wide range of projects, from Department of Defense (DoD) initiatives and Independent Research and Development (IRAD) efforts to personal growth endeavors. “The really cool thing about the SEEDLab is it's there to support not just D projects, but also IRADs and even personal development,” says Alexis. “If you wanted to learn how to use a 3D printer for future projects, you can go in and just learn how to use the equipment.”