It may sound as unexciting as the proverbial “watching paint dry,” but newly gathered long-term image sequences of materials exposed to space conditions on the exterior of the International Space Station (ISS) could help the designers of future spacecraft know what to expect from a new generation of advanced materials.

Until now, detailed research on materials exposed to the harsh space environment has mostly been limited to “before and after” examinations, but the new photographic data showing color variations – gathered at regular intervals during the six-month project – shows how the materials changed over time while exposed to conditions in low Earth orbit.

Led by researchers at the Georgia Tech Research Institute (GTRI), the study’s results will help validate ground-based testing designed to evaluate a new generation of materials that may provide advantages over traditional spacecraft materials. The time-resolved photographic record shows the spectral reflectivity changes while the materials were still in a space environment – before they could be potentially affected by being brought back inside the ISS.

Beyond GTRI, the research team included researchers from the Air Force Research Laboratory (AFRL), NASA, the University of Texas at El Paso, and DuPont, a multi-industrial company headquartered in Wilmington, Delaware. Utilizing the Materials International Space Station Experiment (MISSE) Flight Facility, the research is also supported by Aegis Aerospace Inc., the company which owns and operates the MISSE platform installed on the ISS.

“Sending materials into space is very expensive, so we rely a lot on ground-based facilities to perform simulated space experiments,” said Elena Plis, a GTRI senior research engineer and the project’s principal investigator. Ground-based studies may subject the materials to a half-year’s exposure to space conditions during just a few days. “We knew changes were going to happen to these materials in space, but to what extent the ground-based testing predicted the effects have been unknown.”

Camera equipment that was part of the MISSE-16 mission regularly photographed the samples, which were located in three different locations on the ISS to vary their exposure to space weather. The images were regularly transmitted to Earth, so Plis and other mission scientists had a pretty good idea what to expect when they actually received the samples for more detailed laboratory study in May 2023.

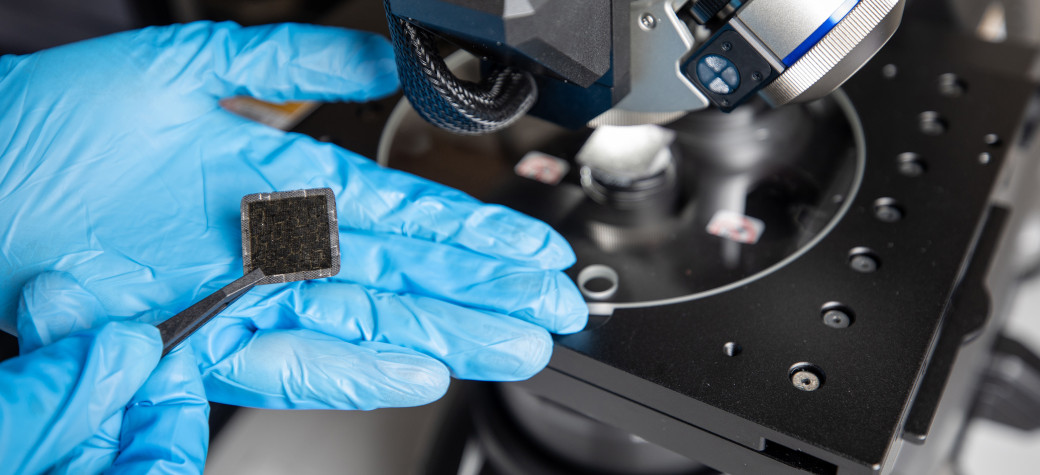

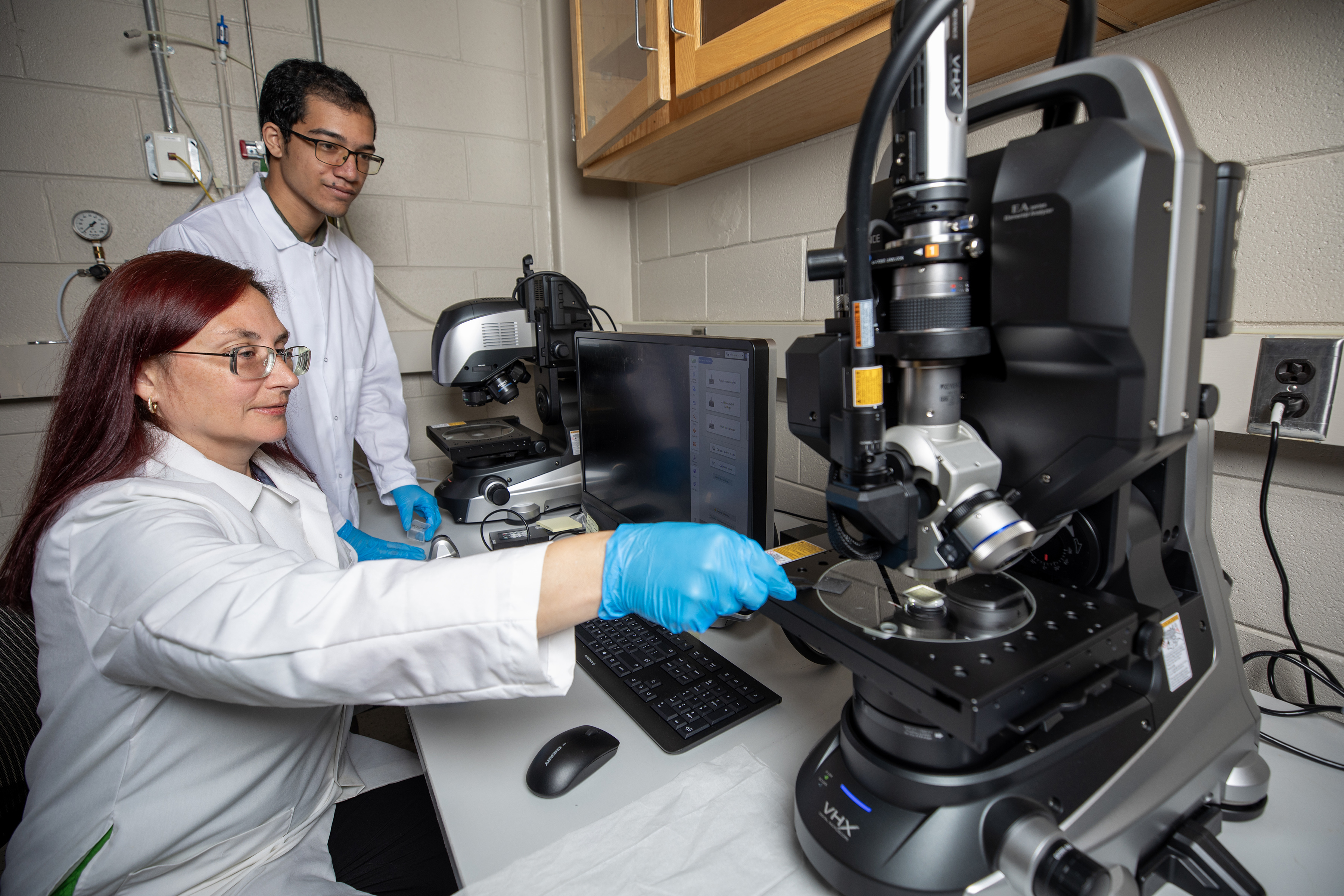

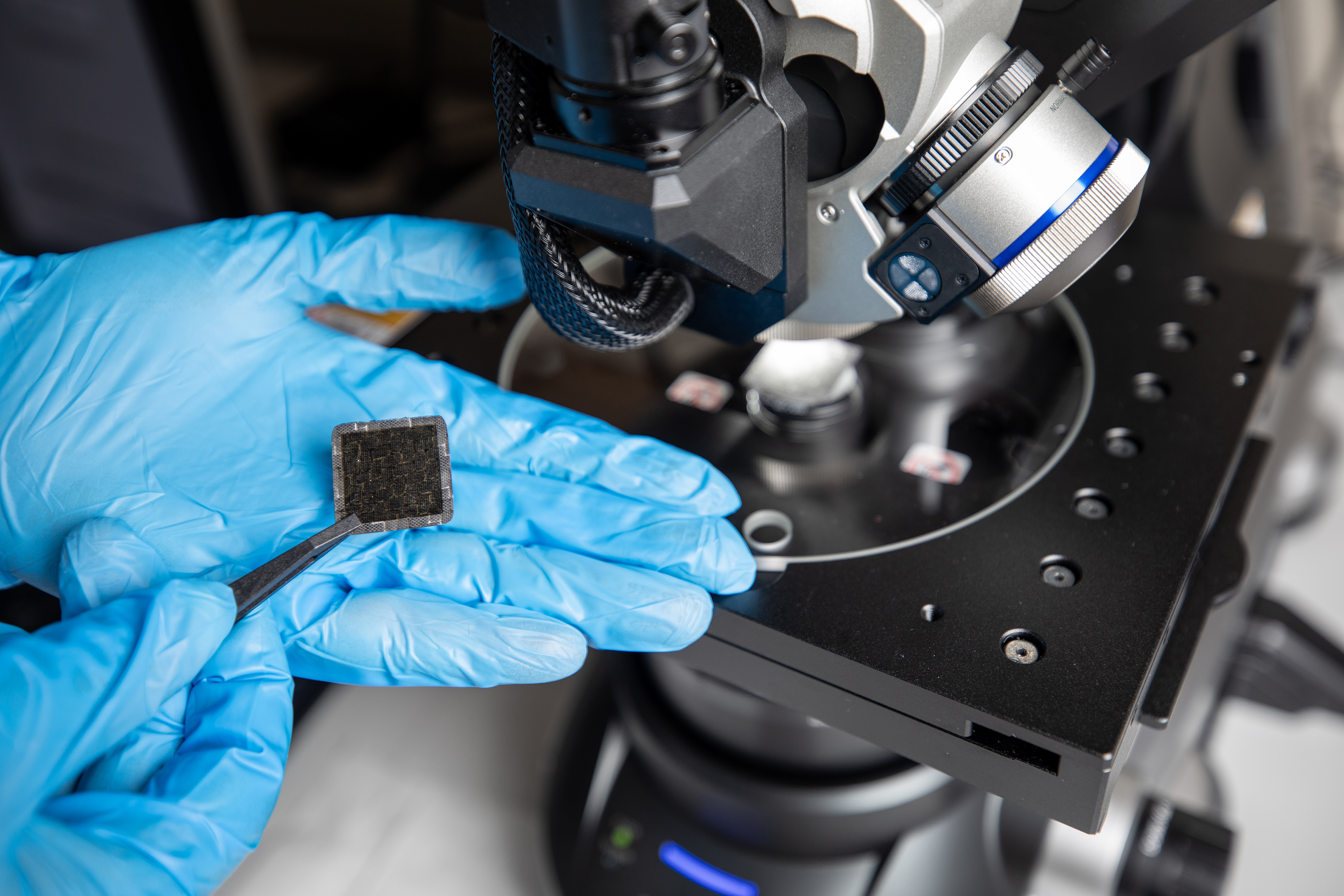

While scientists at the Air Force Research Laboratory conducted directional reflectance measurements on the returned samples, much of the work was done at GTRI by Plis and a team of students who spent the summer characterizing the materials using 3-D microscopes and other instruments. Among the properties examined were surface roughness and erosion, and color changes.

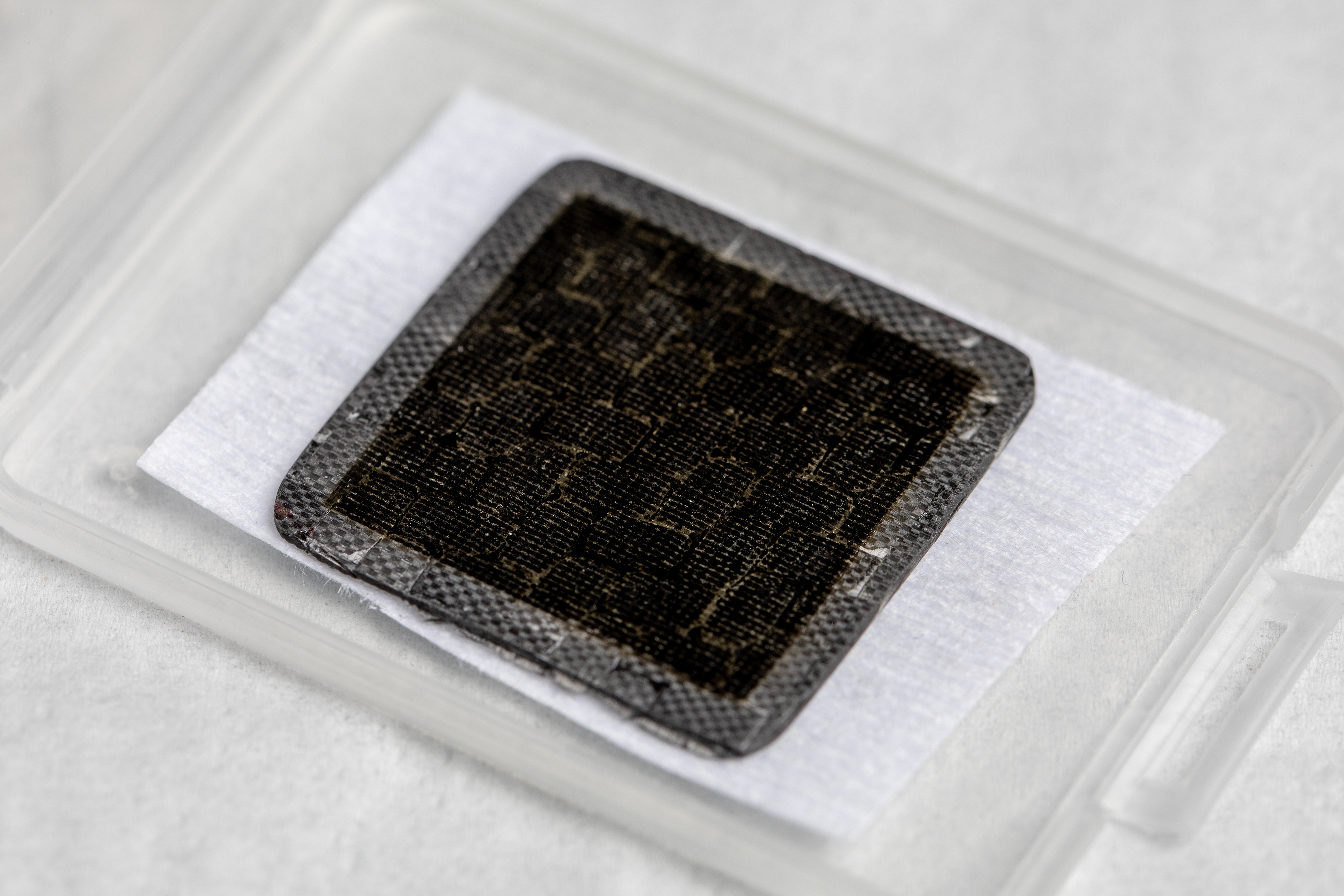

“All the returned materials were changed in their appearance compared to their pristine look,” Plis said. “We were expecting a lot of damage from atomic oxygen, but we also saw that ultraviolet exposure and high-energy electron exposure caused a lot of degradation.”

The extent of color and other changes varied by the chemistry of the material samples, which included polyimides, liquid crystal polymers (LCP), polyhedral oligomeric silsesquioxane (POSS), carbon and glass fiber reinforced polymers, and polyethylene terephthalate (PET) polyester films. Much of the degradation occurred in the first month of space exposure, though the damage continued throughout the six-month period – knowledge that wouldn’t have been available without the regular on-orbit image gathering.

The samples were carried to the ISS on a Falcon 9 rocket launched from the Kennedy Space Center in July 2022. The samples were installed on the exterior of the ISS by a robotic arm and retrieved the same way.

With preliminary data gathered, Plis hopes to continue studying the samples to learn more about how the space conditions affected them. The samples that spent time in space will also be compared to samples subjected to simulated space environment in ground-based labs.

Information gathered from the experiment will ultimately go into MatDB, a database of materials information operated by the U.S. Space Force to help the designers of future spacecraft choose the right materials.

“We now have more materials for which we have information about how they perform in space,” Plis said. “That’s very valuable information and will expand the library of materials available for space. Operating in space is a high-risk endeavor, and designers tend to be very conservative about adopting new materials.”

Beyond helping materials scientists select spacecraft materials, a correlation between color change and material degradation could allow spacecraft structural health to be remotely observed. Such use of optical properties could increase space domain awareness and enable remote diagnosis and anomaly resolution, according to the researchers.

In a follow-on study, a GTRI-led research team now plans to look at how space exposure affects important mechanical properties of materials. That study will follow a similar approach in which samples placed on the exterior of the ISS will be subjected to mechanical deformation and their responses measured. Data from the experiment will be transmitted regularly to scientists on the ground, as was done with MISSE-16 mission.

“We’ll use polarimetric techniques to take images after mechanical deformation and retrieve images that show the strained and stressed materials,” Plis said. “We’ll rely heavily on the heritage of the MISSE-16 project in terms of the optical setup and machine learning techniques we developed to analyze the images. What will be new is a mechanical deformation system to strain the materials at certain intervals.”

The project will be supported by the U.S. Space Force, and partners will include Aegis Aerospace, NASA, the University of Texas at El Paso, and Hedgefog Research Inc (HFR). Researchers will target the MISSE-22 mission tentatively scheduled to be launched in August 2025.

Writer: John Toon (john.toon@gtri.gatech.edu)

GTRI Communications

Georgia Tech Research Institute

Atlanta, Georgia

The Georgia Tech Research Institute (GTRI) is the nonprofit, applied research division of the Georgia Institute of Technology (Georgia Tech). Founded in 1934 as the Engineering Experiment Station, GTRI has grown to more than 2,900 employees, supporting eight laboratories in over 20 locations around the country and performing more than $940 million of problem-solving research annually for government and industry. GTRI's renowned researchers combine science, engineering, economics, policy, and technical expertise to solve complex problems for the U.S. federal government, state, and industry.