Ingenuity from a group of soldiers stationed at Fort Stewart – and help from engineers at the Georgia Tech Research Institute (GTRI) – has produced a possible solution for an issue that affects personnel at multiple U.S. Army facilities located in areas with high humidity and temperatures.

Those conditions can lead to the growth of dangerous mold, which in barracks and other facilities that may be unoccupied due to deployments can damage both soldiers’ personal belongings and Army equipment. Through the 3rd Infantry Division’s (3ID) Marne Innovation and Technology Center, the soldiers and GTRI collaborated to develop a Mold Conditions Awareness Tool (MCAT), a device now being evaluated in large-scale tests at the Army base.

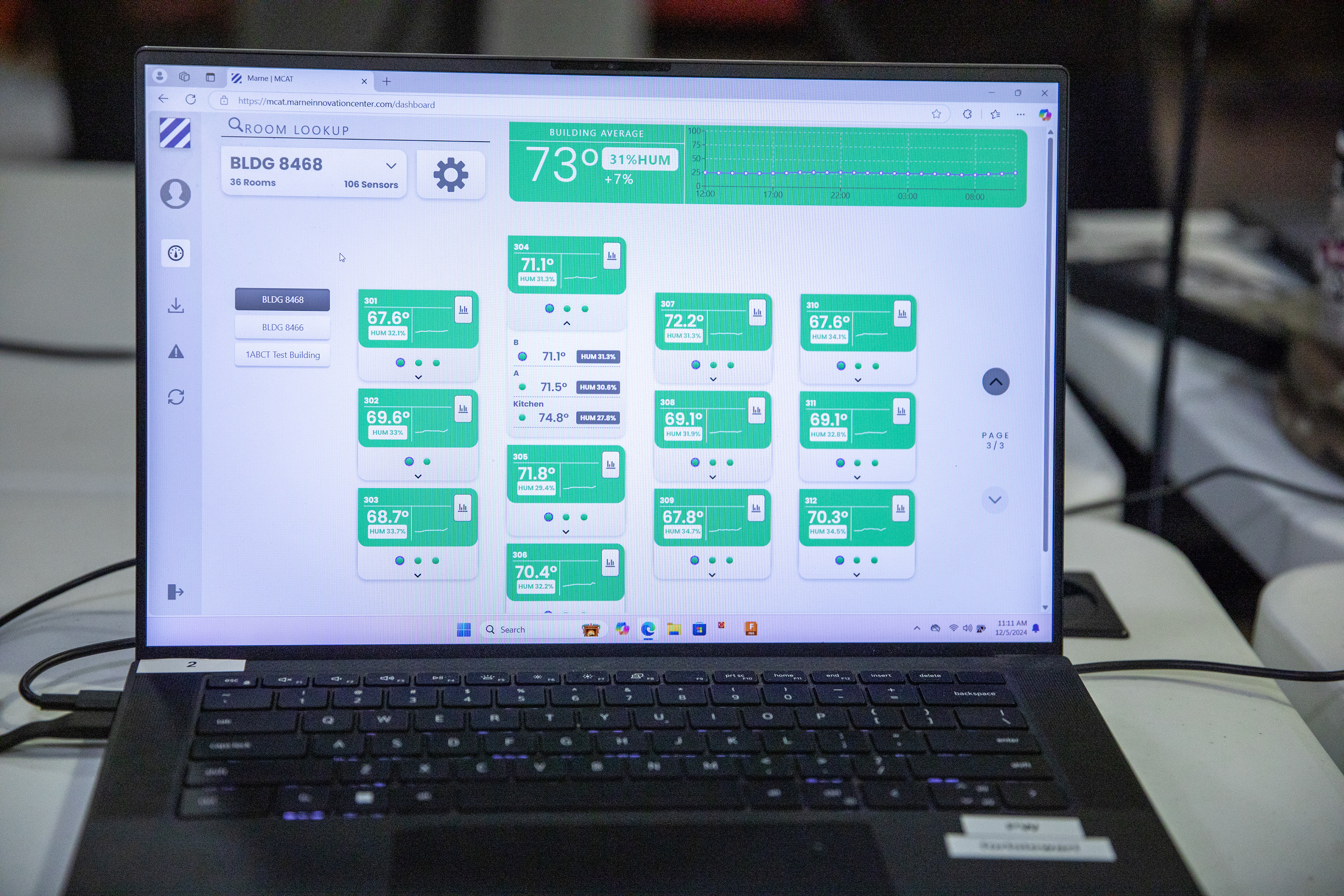

Similar in size to a plug-in air freshener, MCAT includes humidity and temperature sensors integrated with a Wi-Fi transmitter in a small device that can be plugged into existing room power outlets. The device provides data about conditions inside barracks rooms to a central maintenance office. If heat or humidity exceeds levels that can lead to mold growth, maintenance staff are alerted to address the problem, which can result from something as simple as a door or window being accidentally left open.

Watch a video on the MCAT project

“A lot of times, people don’t even realize that mold is growing in the corner of a ceiling or in the floor,” explained Col. Marc Austin, garrison commander at Fort Stewart-Hunter Army Airfield in southeast Georgia. “Through this innovation, we’re going to have real-time information on the conditions in a room, and we can respond before a soldier even knows there’s a problem.”

The MCAT project began in 2022 with an idea from Pvt. Salem Ezz and 1st Lt. Chris Aliperti, both stationed at Fort Stewart. They were aware of mold issues, which can develop quickly in spaces that are unoccupied because of troops’ overseas deployments. Because the barracks have central heating and air conditioning, low-cost, commercially available monitoring solutions were not suitable.

Ezz and Aliperti realized that continuous monitoring in buildings could provide early warning of conditions leading to mold growth, and they developed a prototype sensor to evaluate the concept. The sensor won several awards for innovation – including the XVIII Airborne Corps’ prestigious Dragon’s Lair competition – and was selected for further development by the Marne Innovation Center at Fort Stewart. The center, established to encourage innovation from Army personnel, expanded the testing from a single installation to 10 barracks rooms in 2023.

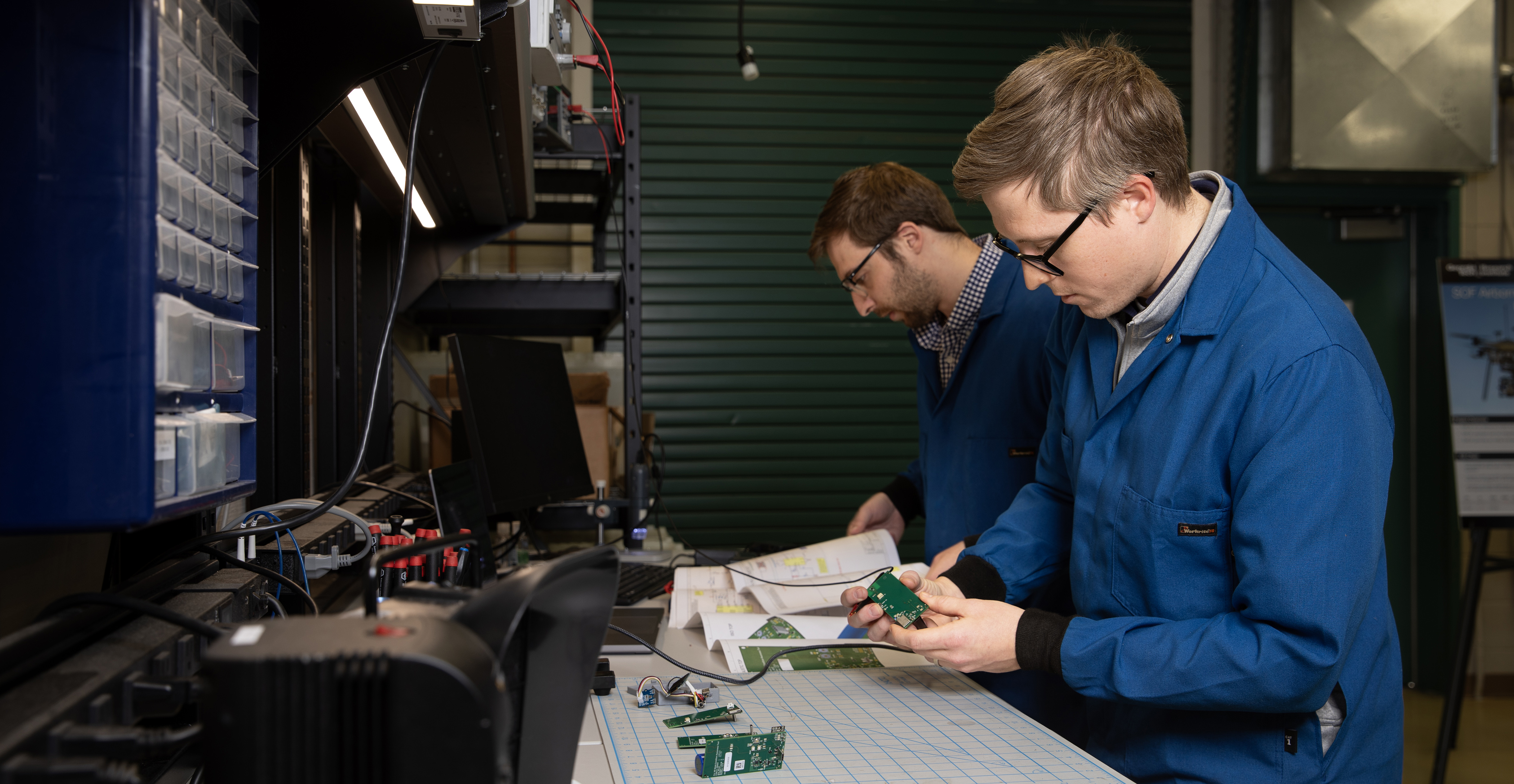

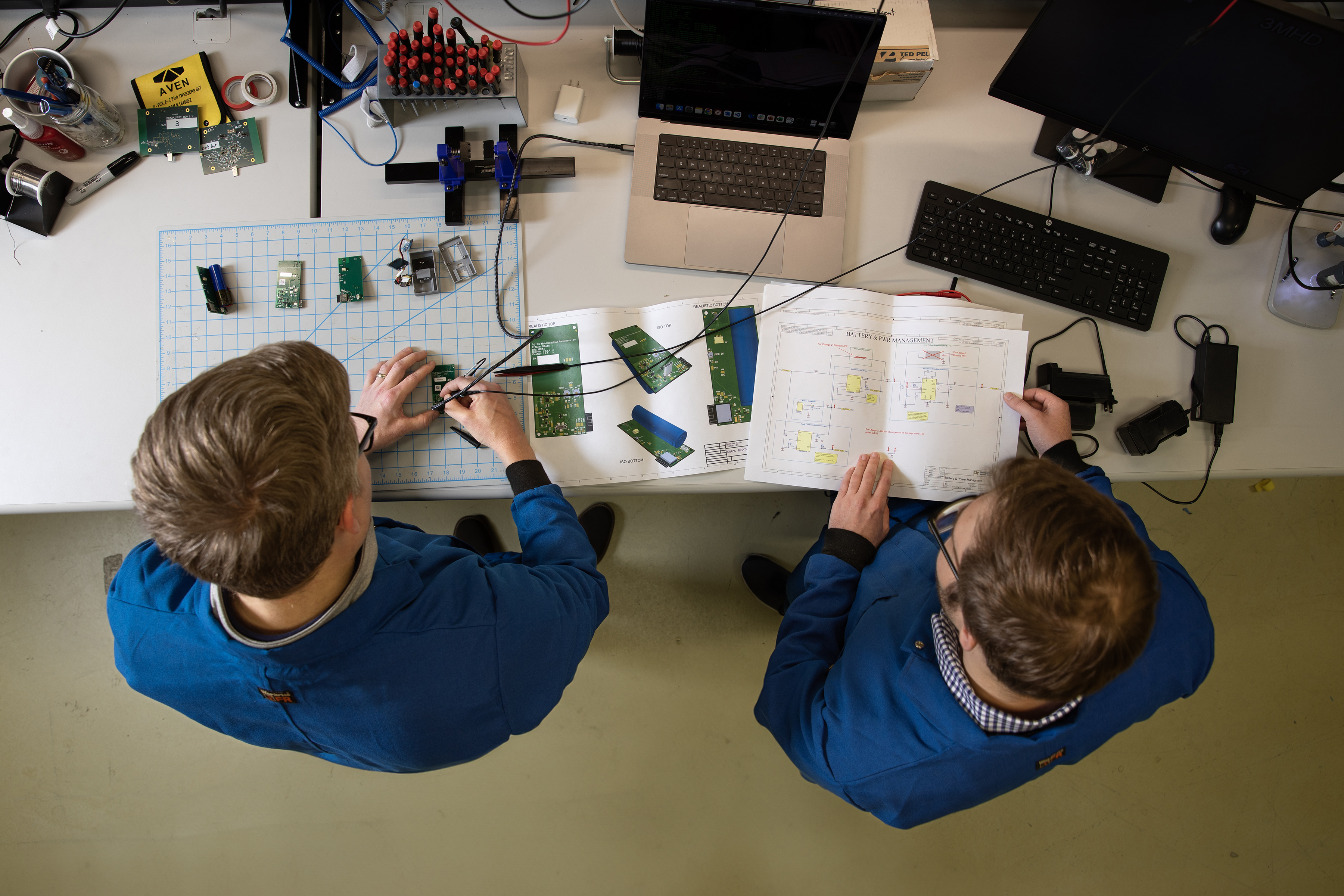

The 3ID team next wanted to scale up the prototyping to make sure MCAT would work on thousands of rooms, so they collaborated with GTRI researchers who had supported other Marne innovation efforts. A research team led by Principal Research Engineer Greg Louden and Senior Research Engineer Andy Chang worked with GTRI Principal Research Engineer Erick Maxwell and Research Engineer Kellen Denny to translate the original prototype into an electronic design that could be mass-produced by a commercial electronics manufacturer.

“Our contribution was to design a single printed circuit board (PCB) that’s fully integrated to incorporate all the functions of their original prototype,” said Chang. “We helped them integrate the new board designed with the software backend and firmware that they developed, and supporting the large-scale prototype that will put approximately 5,000 sensors into the barracks rooms.”

There were a number of design considerations the GTRI engineers had to address. Because the device was intended to measure temperature in the rooms, heat-generating electronic components had to be located away from the sensors. An alternative antenna design was adopted after the first version raised the cost of the PCBs.

Those new sensors, assembled by Fort Stewart personnel using the commercially-produced PCBs and incorporating firmware updates done by GTRI Research Engineer Alex Kernan, are now being installed in more than 3,000 rooms, where they will be evaluated through the coming summertime season to determine if they can fulfill the original mission. If successful, MCAT could be considered for broader implementation not only at Fort Stewart-Hunter Army Airfield, but also at other Army facilities where conditions favor mold growth.

According to its website, The Marne Innovations program “identifies current capability gaps within the 3rd Infantry Division then works with industry and academic partners to rapidly identify, develop, and implement solutions while fostering a culture of a bottom-up innovation: Solving today's problems with today's technology.”

The center recently sponsored its second Marne Innovation Challenge, which included six soldier-led teams from across the 3ID – which currently has 67 active innovation projects created by soldiers who may one day use the new ideas.

“This competition helps foster a culture of innovation across the Third Infantry Division, and hosting events like this helps bring soldiers across the 3ID into a space where we enable them, with tools and training, to help solve their day-to-day problems,” explained 1st Lt. Mallory Moore, deputy innovation officer of the Marne Center.

The MCAT project demonstrates the benefits of encouraging innovation from soldiers in the field who have experience with challenges and ideas for addressing them, Austin explained.

“The chief of staff of the Army wants our units to innovate, test ideas, fail fast, and adapt,” he said. “That reinforces the idea that the best ideas come from the bottom up. Collaboration among multiple ranks and generations through the Marne Innovation Center has allowed us to come up with new concepts, whether they’re MCAT, a new type of drone, or a new way to rearm a helicopter.”

The MCAT devices will be evaluated long-term to determine how well they work, and whether changes may be needed before they are installed across the sprawling facility.

“We want to get the pilot testing complete, then everything installed prior to us getting into the summer humidity,” said Austin, who, as garrison commander, is responsible for the housing and welfare of the soldiers, civilians, and families at the base. “If we can have it in place this spring, we should be out of the pilot phase and fully operational coming out of the new year.”

After the 3ID, the MCAT sensors could be put to use by other Army units. “There are other places we’ve talked with, and they’re looking at how to take the concept and tie it into our production model,” Austin said. “Once we have the data that supports this work, we’ll export it to any garrison or installation that wants it across the Army.”

Writer: John Toon (john.toon@gtri.gatech.edu)

GTRI Communications

Georgia Tech Research Institute

Atlanta, Georgia USA

The Georgia Tech Research Institute (GTRI) is the nonprofit, applied research division of the Georgia Institute of Technology (Georgia Tech). Founded in 1934 as the Engineering Experiment Station, GTRI has grown to more than 2,900 employees, supporting eight laboratories in over 20 locations around the country and performing more than $869 million of problem-solving research annually for government and industry. GTRI's renowned researchers combine science, engineering, economics, policy, and technical expertise to solve complex problems for the U.S. federal government, state, and industry.