There’s more to peanuts than meets the eye – or in this case, nostrils.

All day long, peanut plants emit chemical scents in the form of volatile organic compounds (VOCs) that can provide insight into potential stressors such as drought and disease that could reduce crop yield and lead to significant losses for farmers and distributors.

One disease that is particularly worrisome is aflatoxin, a carcinogen generated by the fungus Aspergillus flavus. Aflatoxin is harmful to humans because it can contaminate crops in the field, at harvest, and during storage, and is more likely develop in conditions where plant water supply is unpredictable. According to recent estimates, aflatoxin takes as much as $126 million out of the U.S. peanut industry each year, but current detection methods are costly and inefficient. Researchers at the Georgia Tech Research Institute (GTRI) and University of Florida (UF) are working to change that.

“The aflatoxin detection process as a whole, from sample prep to analysis to developing a finalized data report, can be labor intensive, time intensive and expensive,” said Christopher Heist, a GTRI research scientist who is supporting the project. “Being able to better predict and detect aflatoxin earlier in the peanut production process will be critical to breaking that cycle.”

VOCs can be likened to smells or fragrances that are distinct to each peanut plant. However, because the plants emit thousands of these smells, it can be difficult to pinpoint which scents indicate a potential aflatoxin infection. As a result, many farmers treat the entire field for infection, impacting both healthy and infected plants and losing money in the process.

Some farms also outsource detection to third-party laboratories, which collect plant samples and transport them to a lab for an analysis using a technique known as high-performance liquid chromatography (HPLC). HPLC is an analytical chemistry technique used to separate, detect and quantify each component in a sample.

“With HPLC, the labs have to get all the chemicals into a liquid state, run the liquid into a column, separate it, and then identify the chemicals using a detector,” explained Daniel Sabo, a GTRI senior research scientist who is leading the project. “From start to finish, that process can take anywhere from a couple of days to a couple of weeks.”

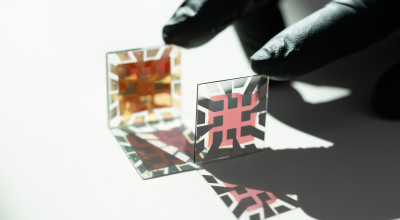

GTRI has developed a collection technique that utilized glass rods called Twisters® that are coated with gas-absorbent material to capture VOCs so that they can be tested for potential aflatoxin contamination. In recent field tests, GTRI successfully demonstrated the Twisters® could capture VOCs to be analyzed for the detection of mild to severe drought stress and aflatoxin contamination in peanut plants, as well as aflatoxin contamination in peanut pods and nuts post-harvest.

The research team’s next steps are to standardize its VOC measurement process and develop low-cost sensor platforms that would allow farmers to test for aflatoxin in the field.

“What we’re trying to do is use the Twisters® to figure out what those key features or chemicals are that we need to be looking for in peanut plants,” said Sabo. “Then we could use that information to develop specialized sensors that test specifically for those chemicals.”

GTRI has partnered with UF’s Agronomy Department to experiment with VOC collection methods in its outdoor field site, environmental chamber and greenhouse on its campus in Gainesville, Florida.

William Hammond, an assistant professor of plant ecophysiology in UF’s Agronomy Department, said UF’s expertise in plant ecophysiology, or the study of how plants interact with their environment, combined with GTRI’s knowledge in collecting and analyzing VOCs, could allow for earlier detection of aflatoxin formation in peanut plants.

“Working towards early warning systems via VOC detection and/or better understanding the plant-environment interactions, could allow the industry to identify the risk of aflatoxin formation earlier than is presently possible,” Hammond said.

Looking ahead, Heist and Sabo said they expect robots to play a role in conducting targeted, in-the-field testing for farmers, which could further reduce costs and minimize the environmental impact of aflatoxin treatment. GTRI envisions farmers would use robotic systems to geotag locations where aflatoxins are most concentrated and direct the robots to apply fungicide only in those specific areas.

“It's hard to put a timeline on when this might happen, but it’s a very interesting area for us and we look forward to working with the many roboticists in our division to solve this challenge,” Heist said.

Writer: Anna Akins

Photos: Sean McNeil

GTRI Communications

Georgia Tech Research Institute

Atlanta, Georgia

The Georgia Tech Research Institute (GTRI) is the nonprofit, applied research division of the Georgia Institute of Technology (Georgia Tech). Founded in 1934 as the Engineering Experiment Station, GTRI has grown to more than 2,900 employees, supporting eight laboratories in over 20 locations around the country and performing more than $800 million of problem-solving research annually for government and industry. GTRI's renowned researchers combine science, engineering, economics, policy, and technical expertise to solve complex problems for the U.S. federal government, state, and industry.