Amid the COVID-19 pandemic, hospitals and health care workers are facing a shortage of face masks, face shields, and other materials known as personal protective equipment (PPE). In response, many scientists, designers, and researchers around the world began innovating solutions.

The Georgia Institute of Technology (Georgia Tech) jumped into action to address the need for PPE. As a member of the Georgia Tech community, the Georgia Tech Research Institute (GTRI) quickly began asking questions, identifying ways the Institute could aid in the efforts. By Monday, March 23, a team had been established to address three different aspects of PPE — face shields, mask cartridges, and face mask design. GTRI engineers are also working on designing low-cost ventilators and other medical equipment that is needed for the pandemic.

The goal is to design and build effective PPE that could also be mass-produced, substituting expensive materials with cheaper but effective ones, and time-consuming procedures with do-it-yourself (DIY) strategies in an effort to address the PPE shortage.

Dennis Denney (left), assistant director of GTRI’s Machine Services, and Jeff Wilkie (right), machine shop supervisor, wear a face shield prototype for first responders to verify its comfort and fit. (Credit: Dennis Denney)

Adapting the face shield research that began in the mechanical engineering department at Georgia Tech, GTRI Machine Services began manufacturing and fabricating masks, modifying the design for mass production, and completing an initial batch of prototypes.

GTRI is also working to address replacement N95 cartridges for the 3M 600 series mask. With a team covering government and industry, GTRI is collaborating on a new design at the forefront of development.

Jonathan Holmes, a senior research engineer at GTRI’s Aerospace, Transportation, and Advanced Systems (ATAS) lab, said that this experience has taught him and his team more about the N95 cartridges and how they can be built with different kinds of filter materials that can be more economical and efficient than the standard filter media.

The endeavor comes with certain challenges, however. Nurses and doctors typically discard multiple face masks a day since standard fabric masks are designed to be disposable. To save material and extend the life of critical equipment, Holmes said that GTRI is designing a two-piece N95 respirator, where the mask portion can be reused, and only the filter cartridges are disposable.

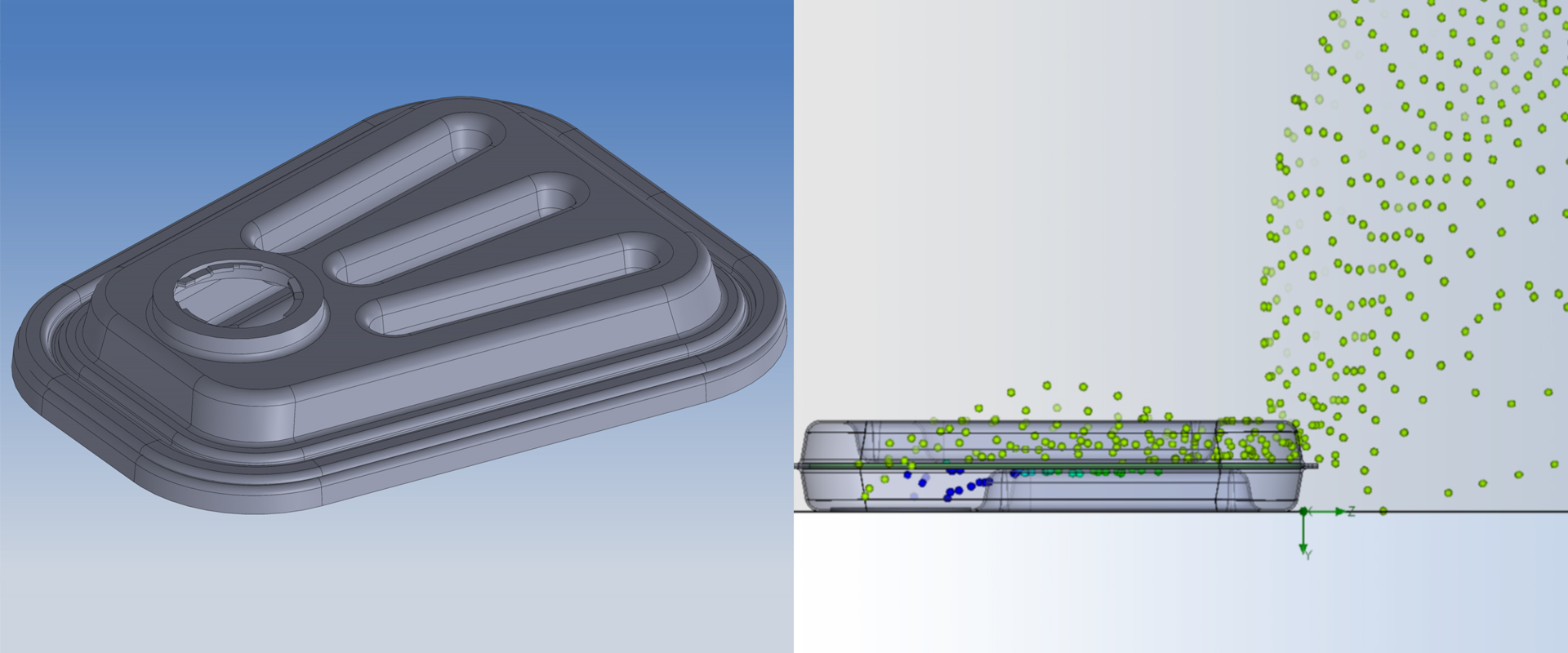

Left: A proposed design for the N95 cartridge for the 3M 600 series mask. Right: Flow analysis of the N95 cartridge.

There’s also a steep learning curve. GTRI engineers are taking in copious amounts of data to learn about their PPE assignments and then using that information to inform their designs. Holmes said that the Georgia Tech Library has helped with some of that data compilation.

“You know, we kinda consider ourselves a jack-of-all-trades, in that we have to do a lot of different things,” Holmes said,” and I think that GTRI provides the opportunity for more people to exist like that — that aren’t just extreme specialists in some areas, but that they can contribute in a lot of areas.”

Every day, additional people test positive for COVID-19 in the United States, increasing the demand on the country’s health care system. The Georgia Tech community is in a race against time to put their proposed PPE designs into production and then get them out to the hospitals and health care facilities that desperately need them, and much of GTRI’s work on this project has been volunteer.

“There’s a very real sense of, if not now, then when?” said Holmes’ teammate, Kyle Azevedo, a senior research engineer at ATAS. “There’s no better opportunity to do what we can do to help out our communities, both local and nationwide.”

A simple, low-cost ventilator based on the resuscitation bags carried in ambulances – and widely available in hospitals – has been designed by an international team of university researchers. (Credit: Steven Norris, Georgia Tech)

Even though this project was designed as a rapid response effort, the testing process needs to be iterative, Azevedo said. Teams from the Georgia Tech academic community have been designing the equipment before working with GTRI researchers to construct prototypes and make necessary adjustments.

For example, some adjustments have been proposed for the N95 cartridge designs to make the masks more comfortable and cause less chafing for the wearer. Georgia Tech engineers have also made tweaks to the face shields so they could be more easily mass-produced.

Like many whose lives have been impacted by the spread of COVID-19, also known as the coronavirus disease, Georgia Tech researchers and engineers have had their lives flipped upside-down and are having to adjust to changes in their work lives.

Avezedo counts himself lucky that he and his immediate family have not been severely impacted by the pandemic, though he is facing some challenges while working from home.

“My wife and I are both working professionals,” he said. “We’ve really been struggling to juggle that with taking care of a 2-year-old and a 4-year-old, and seeing the size and effect of society shutting down. I think it’s something that we’re not going to forget for a long time.”

Despite the challenges, Holmes, Azevedo, and other GTRI staff remain committed to serving the community through this PPE effort, with hopes that they can make an impact during these difficult times.

“The shortage of medical equipment is real, and it has a real effect on the ability for health care facilities to care for their patients,” Azevedo said. “We’re extremely motivated to work as hard as we can because if we do succeed, then this could translate to any number of people that get more effective care and possibly even survive — that wouldn’t have otherwise.”

They know they are not alone in this endeavor, and they have the support of the community around them, including others in GTRI and in the Georgia Tech community, private businesses, government institutions, and other organizations that are contributing to this effort.

“I think I can speak for the whole team in saying that we’re all really driven by the hope that we can make a difference,” Azevedo said.

Katrina Heitz contributed to this article.

RELATED LINKS

Responding to COVID-19

The battle against COVID-19 is a worldwide challenge unlike any in living memory. The Georgia Tech community has joined the fight, contributing our expertise, innovation, and indomitable spirit to the effort.

Georgia Tech Community COVID-19 Response

Georgia Tech has established a Rapid Response website to identify needs for personal protective equipment and potential collaborations.

Georgia Tech Produces Key Components for Governor’s Coronavirus Test Initiative

April 22, 2020 - Gaps in the supply of coronavirus tests are propelling initiatives to fill them across the country.

Will Smartphones Help Us Keep COVID-19 Under Control?

April 20, 2020 - The smartphones carried in so many pockets and purses could play a key role in keeping COVID-19 under control as the nation cautiously reopens the economy.

Do-It-Yourself Medical Devices and Protective Gear Fuel Battle Against COVID-19

March 23, 2020 - A research team from the Georgia Institute of Technology and other universities across two continents is racing to develop “do-it-yourself” health care gear that can be assembled where it’s needed from components available locally.