GTRI News & Features

01.24.25

GTRI 2024 Annual Report

The digital edition of GTRI's 2024 Annual Report provides an overview of our accomplishments, research investments and outreach programs.

Read More >>Media Inquiries

GTRI News

- News stories

Gary Ashworth, who most recently served as Acting Secretary of the Air Force, will join the Georgia Tech Research Institute (GTRI) as its Director of Washington Operations… Read More >>

- News stories

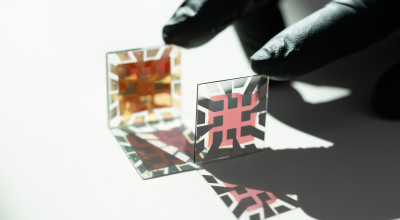

Georgia Tech researchers will soon be sending 18 photovoltaic cells to the International Space Station (ISS) for a study of how space conditions affect the devices’ operation over… Read More >>

- News stories

GTRI's latest Military Graduate Research Program (MGRP) cohort took on defense challenges with real-world impact. Three cohort members share their experiences. Read More >>

- News stories

On June 7, GTRI celebrated the U.S. Army's 250th birthday in Huntsville, Alabama, despite severe weather conditions. Read More >>

- News stories

GTRI is proud to welcome Stephanie Geigel, a U.S. Army veteran who joins our Office of the CIO through the Hiring Our Heroes program. Read More >>

- News stories

GTRI salutes its researchers who have recently achieved level advancement. Read More >>

- News stories

GTRI Operations Manager Rafael (Rafa) Dominguez, a self-described "rugby enthusiast," recently donated new uniforms to the Georgia Tech Rugby Club. Read More >>

- News stories

GTRI's Hives Early Career Independent Research and Development (IRAD) Program equips researchers who are in their first six years of employment to lead projects focused on… Read More >>